DIFFERENT CONCRETE LEVELING OPTIONS: PROS, CONS, AND COSTS

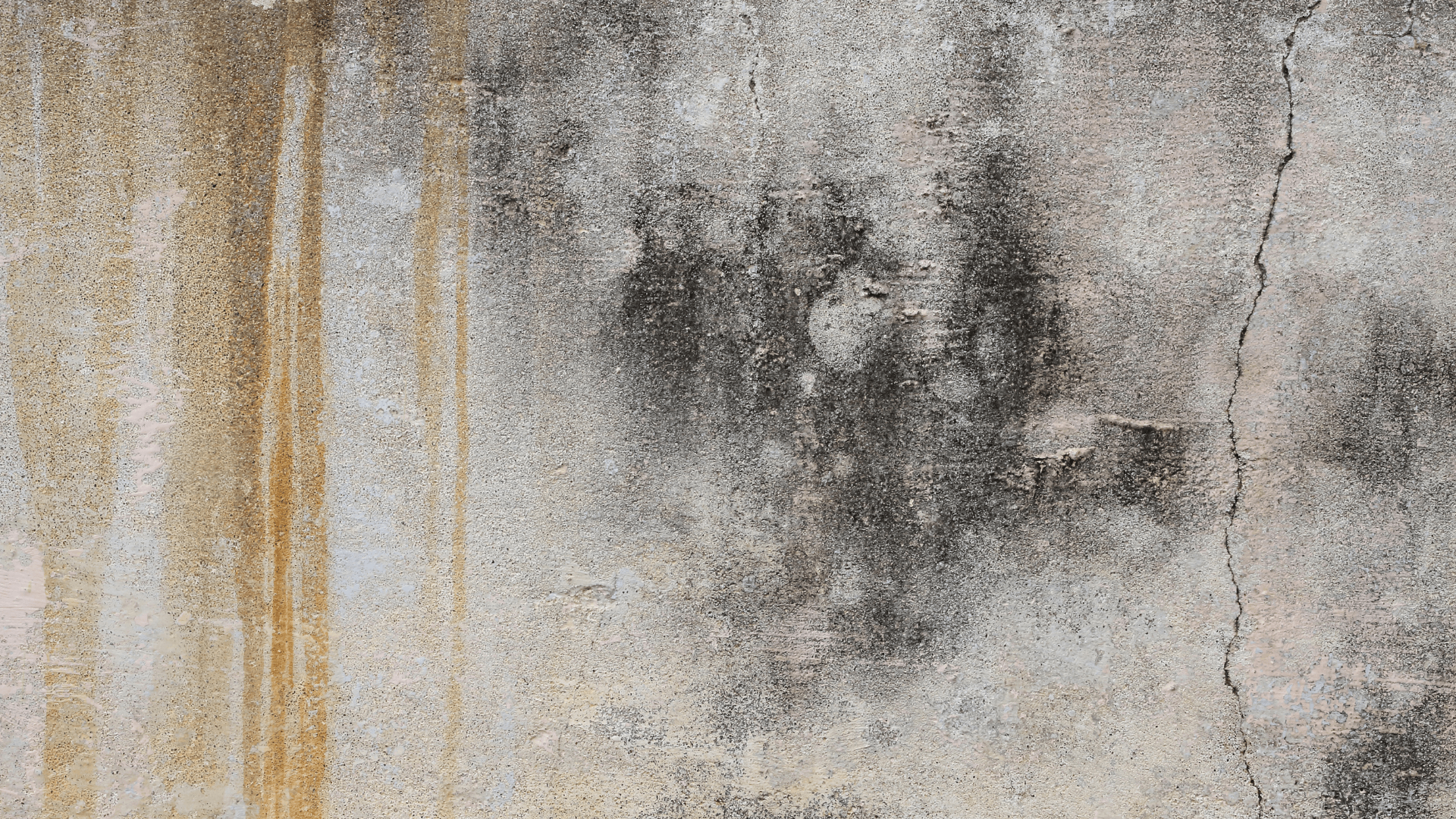

Are you noticing that some of your concrete slabs are no longer on the level of those around them?

An uneven walkway with crooked concrete, a broken driveway, or a sloping patio are defects that are tough to overlook. There is no need to replace the concrete in most instances; however, the concrete leveling process may be the solution to fix the problem.

In this blog, we'll describe how concrete leveling can be the solution you're looking for to get your concrete back in place—naming various types of concrete leveling, their advantages and disadvantages, costs, and much more!

What exactly is the concrete leveling method and how does it work?

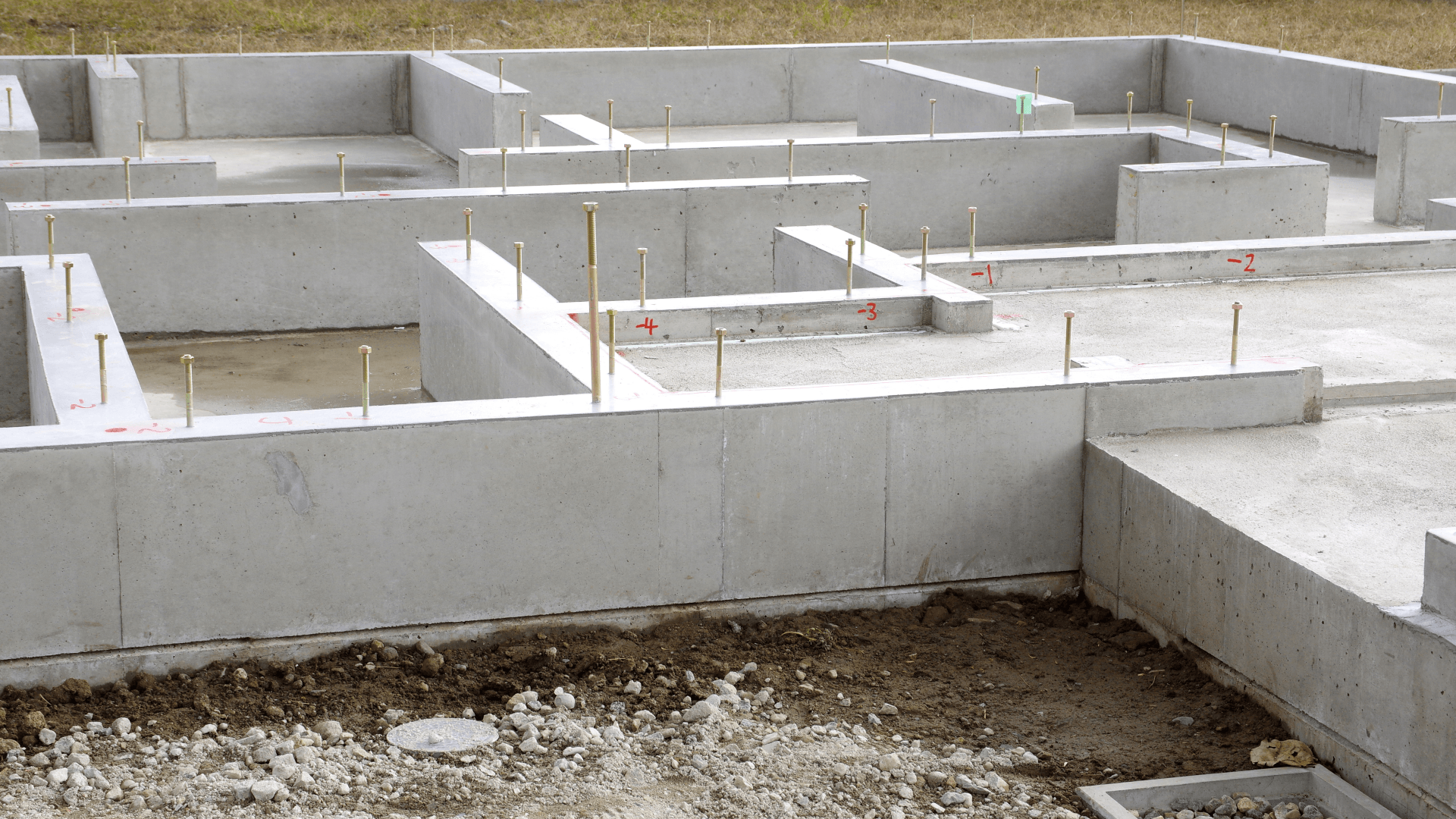

Concrete leveling works by injecting a leveling substance while filling holes beneath drooping concrete slabs such as stairs, porches, patios, sidewalks, and driveways. The substance injected stabilizes loose soil and returns the sunken slab to its original level.

This process is highly recommended on many occasions. Due to various causes, concrete slabs can sink and become uneven over time. Water draining away the soil that supports a slab is a common reason. Sometimes, soil or tree roots grow or shrink, causing slabs to shift.

Different Concrete Leveling Options

1. Mudjacking

Mudjacking is the process of elevating concrete from the ground using a mud-like mixture of cement, water, soil, and sand. Initially, multiple two-inch-wide holes are drilled into the existing concrete slab. Then the material is injected through the holes to raise the slab from underneath, returning to its original height.

The benefits of this method are the cheaper costs compared to polymeric leveling or total slab replacement, the stability, the avoidance of heavy equipment, and not requiring a massive workforce.

On the other hand, drilling huge holes might produce cracks in your slab if not done correctly, and the material is not waterproof and can deteriorate.

This procedure is unsuitable for garage floors, basements, foundation repairs, pools, or severely damaged slabs.

2. Poly Leveling

Poly leveling, often known as polyurethane foam concrete leveling, is another concrete leveling procedure: Small holes are drilled into the slab, and later injecting, polyurethane foam into the holes, which expands to level the sunken concrete.

The advantages of this method are that it does not require heavy equipment or significant personnel. Also, its durability may endure for at least ten years, its waterproof foam is exceptionally lightweight, and it works for basements, garage floors, pools, and foundation problems. The downside is that it is more expensive than mudjacking and will not work on highly damaged slabs.

3. Limestone Grout Leveling

This process combines crushed limestone, sometimes known as agricultural lime, with water and (in some cases) Portland cement to make a slurry consistency similar to a thick milkshake.

Because of its semi-fluid nature, this slurry pushes against itself, filling gaps beneath the slab as it is injected hydraulically (beneath the slab through 1" holes). Once the space is filled, pressure rises, gradually lifting the slab into position.

The advantages of limestone grout leveling are that it produces smaller holes than mudjacking, is environmentally friendly, and is cost-effective. Additionally, it creates a solid foundation for the concrete slab after the limestone grout dries up. The disadvantages of stone slurry grout leveling are that it takes more tidiness than foam leveling and that rainwater can degrade limestone leveling materials, leading to re-settlement.

4. Expanding Structural Foam Leveling

Polyurethane is used in the injection process for foam leveling. A two-part polymer is injected via a hole smaller than one inch in diameter. Although the substance is injected at a higher pressure than standard cementitious grout, the pressure is not what produces the lifting. The real lifting action is performed by the expansion of air bubbles in the injected material below the slab surface, as the liquid resin reacts and produces a structural foam.

The advantages of this concrete leveling method include longer guarantee terms with polyurethane foam, less clean-up, and the fact that it does not hold moisture or deteriorate when exposed to rainwater.

The disadvantages include the need for exceptionally experienced experts to install it correctly, the fact that polyurethane is plastic and environmentally unfriendly, and that it can attach to and permanently discolor other adjacent surfaces.

Benefits of Concrete Leveling Compared to Concrete Replacement

When you discover cracks and damage to an area of your concrete sidewalk, driveway, or parking lot, you may assume that replacing the entire work is the only option to finish the repairs. But considering concrete leveling can do the magic.

There are several advantages to concrete leveling, which include:

- Cost-effective

- Repairs are completed in less time

- Possibly environment-friendly

- Improved curb appeal

- It's more convenient and less disruptive

Is Concrete Leveling Cost-Effective?

Yes! Concrete leveling is often preferable versus total slab replacement if your slab is still in good condition. With total slab replacement, you'll pay to have the old slab removed and disposed of, new concrete delivered, and a new slab poured as part of the replacement cost.

Concrete leveling will save you money at the expense of replacing everything. At $3 to $6 per square foot, mudjacking is the most affordable choice. Poly leveling costs between $5 and $25 per square foot, and so on.

Contact Concrete Contractors of Fargo for Your Concrete Needs!

We provide the highest quality workmanship at the most reasonable prices and a 100% satisfaction guarantee on all our work. We will fix your concrete problems straight away, and we will make sure the underlying issues are addressed!

Never put off dealing with what could be more significant problems down the road. Call Concrete Contractors of Fargo, ND, at (701) 409-1626 for more information on our concrete leveling process or speak with a team member.