CONCRETE TYPES AND USES

Concrete may be found practically anywhere: buildings, bridges, walls, swimming pools, roadways, airport runways, floors, patios, and even a house.

Selecting the correct type of concrete for your business or residential project helps offer the maximum durability and lifetime for these uses. Working with a reliable Concrete Contractors Fargo team can provide you with the most accurate guidance and assistance throughout your building process.

What exactly are you looking for?

Here are some broad suggestions about the various types of concrete and their most practical applications.

Types of concrete

Many varieties of concrete can be used for the same purpose. It all depends on what you want to accomplish. You can select the suitable type of concrete to complete the work.

Plain Concrete

Common concrete is a form of concrete that employs the standard 1:2:4 mix design with cement, sand, and gravel as its components. It can be used to produce pavement or structures if the tensile strength is not required. This form of concrete is extremely durable and has a high rating.

Reinforced Concrete

This type of concrete is used in the construction of buildings, bridges, and highways. This type of concrete's strength is increased by embedding wires, steel rods, or cables in the concrete before it hardens. These things are most often known as rebar.

Fibers have been employed to strengthen this concrete. They form a strong connection, and as a result, the two materials can withstand a wide range of applied forces.

Lightweight Concrete

Lightweight concrete is defined as any type of concrete with a density of less than 1920 kg/m3. Aggregates are materials that are used to improve the density of a concrete style. Natural elements such as scoria or pumice, artificial materials such as clay and expanded shale, and processed minerals such as vermiculite and perlite are examples of lightweight aggregates.

Lightweight concrete is commonly used in the construction of long-span bridge decks and building blocks. It may also be used to keep steel structures safe.

Prestressed Concrete

Prestressed concrete is made using a unique technique. Just like reinforced concrete, it has bars or tendons. However, these tendons are stressed before the pouring of the concrete. When the concrete hardens, this unit is compressed. This technique strengthens the lowest part of the unit against tensile pressures.

It does, however, need heavy machinery and specialized workers. Prestressed units are often produced and built on-site. Prestressed concrete is used to construct bridges, heavy-duty construction, and long-span roofs.

Asphalt Concrete

Asphalt is a black material made up of a combination of hydrocarbons known as bitumens. This is a type of concrete that is typically used on roadways, airport runways, highways, parking lots, and walkways. The need for asphalt developed in tandem with the motor industry. Despite its durability, it still needs a carefully prepared combination of gravel and asphalt.

Precast Concrete

The advantage of using precast concrete is the quickness with which it can be assembled. This type of concrete is manufactured and cast in a factory to specific standards and is then delivered to the construction site and assembled.

The units are of very good quality because they are created in a factory.

Air-Entrained Concrete

In certain concrete types, every cubic foot contains billions of small air cells. These small air pockets ease the concrete's internal pressure and create microscopic chambers for water to expand as it freezes. Almost all concrete used in freezing or freeze-thaw environments is air-entrained. Various foaming additives are used during the mixing process to entice air into the concrete.

Ready-Mix Concrete

Ready-mix concrete is concrete that has been produced and polished at a centrally located factory. This concrete is mixed as it is carried to the site in the familiar cement trucks visible on roads and highways. Because the cement does not require further preparation, it may be utilized as soon as the trucks arrive at the job site.

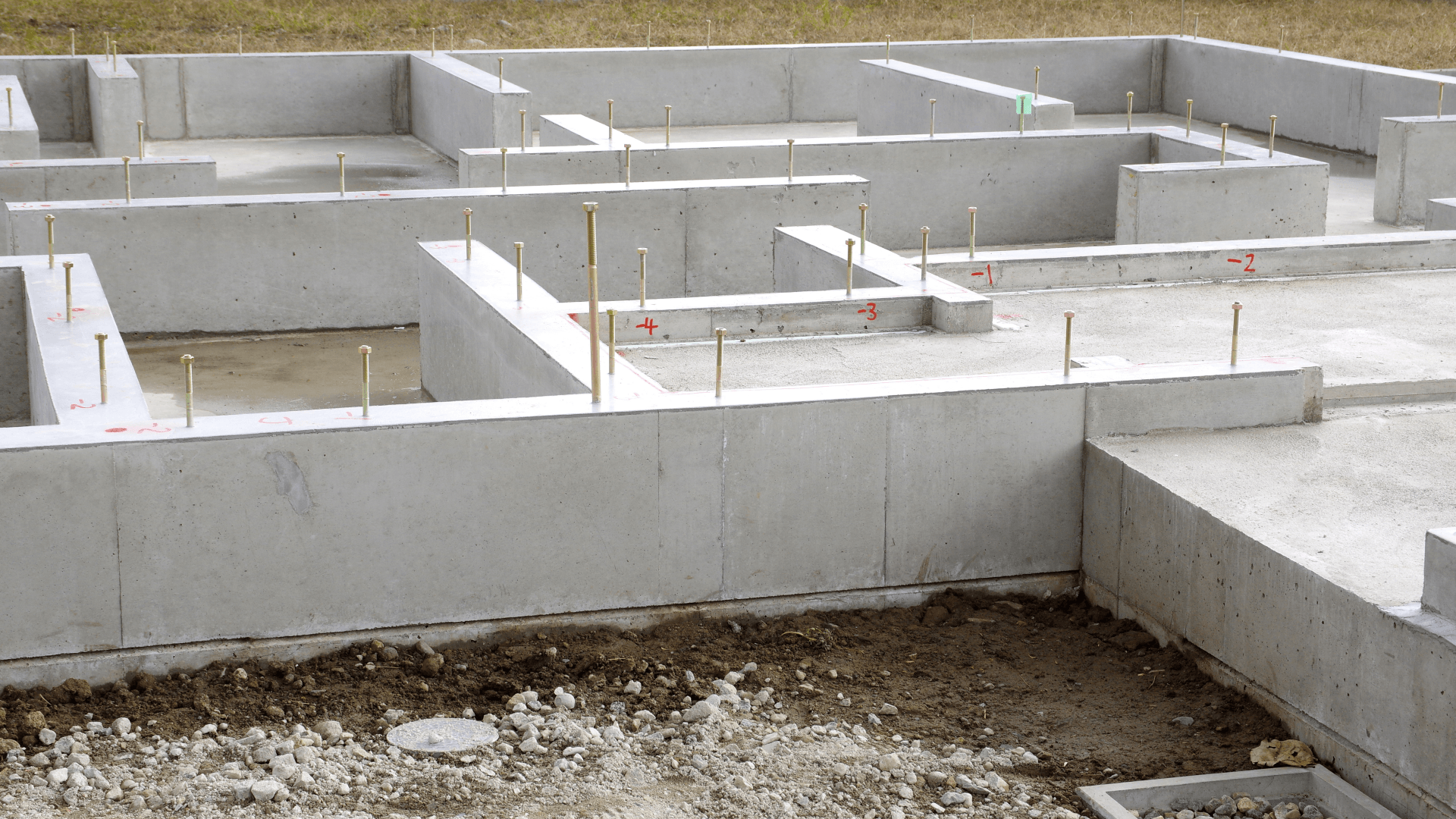

Volumetric Concrete

Volumetric concrete is an alternative to ready-mixed concrete that can be transported between the factory and the building site.

It was developed to solve the issue of great distances between the concrete factory and building sites. Because the concrete may be made and supplied on-site as needed, a single truck can create two distinct concrete mixtures. It is extremely beneficial on big building sites, basement builds, and multi-projects where multiple grades of concrete are required.

Decorative Concrete

Decorative concrete is used to make visually and aesthetically pleasing concrete mixtures. Coloring, molding, polishing, and other procedures can be used to decorate concrete. It's great for any project where you want to make a visual impact. Swimming pools and floors, for example, can greatly benefit from beautiful concrete.

Rapid-Set Concrete

Quick-set concrete is ideal for building projects as it offers faster set times and is resistant to low temperatures, allowing it to be utilized at any time of year. It's especially handy in the winter when the cold weather prevents you from using many other types of concrete.

Smart Concrete

This is the next generation of concrete technology. It provides an alternative way of tracking the condition of reinforced concrete structures. While it is not currently widely accessible, it has the potential to become the building material of the future for places that suffer from a high risk of earthquakes. Engineers in cities may use smart concrete to examine the state of structures following earthquakes.

Pervious Concrete

Pervious concrete is made up of a porous structure and lacks sand, resulting in an open-scale, porous structure. It is intended to address the issues of stormwater runoff, pools of water, and puddles. Pervious concrete roads offer fewer issues with hydroplaning, tire spray, and snow buildup.

Pumped Concrete

If you've ever wondered what cement combinations are used in the flooring of a tall structure, the answer is most likely pumped concrete. The trick to pumped concrete is that it is extremely workable, so it can be readily carried to a higher floor via a pipe. This pipe will be a flexible or stiff hose that will discharge the concrete to the desired location.

Limecrete

It is mostly used to build floors, vaults, and domes. Limecrete offers several environmental advantages since it is easy to clean and renewable. It can also be used in conjunction with radiant floor heating.

Roll Compacted Concrete

Roll-compacted concrete is used for roadworks, airport runways, car parks, pavements, and industrial maintenance. This concrete produces fewer emissions, which improves the environment. It is a strong, thick concrete that is utilized on regularly used roadways with heavy cars.

Glass Concrete

Glass concrete is a more contemporary type of concrete that uses recycled glass. This concrete can have shiny or colorful glass implanted during the mixing process to give it a characteristic burst of color or glitter. Glass concrete is commonly used in large-format slabs used in flooring or on architectural façades.

Shotcrete Concrete

Shotcrete type of concrete can be used to build steel constructions. It is also typically utilized when access to a work area is difficult or when the formwork is infeasible or unnecessarily expensive. A shotcrete nozzle is used to spray shotcrete onto a frame or formwork.

Ultra-High Performance Concrete

This is a new type of concrete that has gained popularity in recent years due to its extraordinary strength and durability features. In addition to rapid bridge construction and structural rehabilitation, this high-performance concrete type can also be used for a variety of other uses.

High-Density Concrete

High-density concrete is commonly used in the construction of nuclear power plants. The use of heavyweight aggregates helps the structure's resistance to radiation. The crushed rock most frequently used is barytes, a colorless or white substance composed of barium sulfate, the main element in barium.

Contemplating What Type Of Works Best For You? Call Us!

As you can see, there are several concrete types and their uses that you may select for your Fargo foundation repair, stamped concrete repair, concrete patio installation, or driveway replacement for your building or house.

If you are unsure which one is ideal for you, contact us at Concrete Contractors Fargo, ND; we can provide the best options for your needs.

Call us today at 713-227-1122 for a free quotation on your next Fargo, North Dakota concrete construction job! A member of our team will contact you in no time.