COLD WEATHER CONCRETE WORK

Pouring concrete for any construction project necessitates meticulous planning. Can you imagine how difficult it is to pour concrete in cold weather?

Temperature changes are taken into account in every concrete job since they might affect the curing process and the ultimate result. Certain steps can be taken to guarantee that concrete poured during the winter works just as well as concrete poured at any other time of year.

This post will go over everything you need to know about cold weather concreting. Common cold-weather concreting mistakes, the adverse effects of cold weather on concrete, recommendations for successful cold-weather pours, and much more!

What is "Cold Weather Concrete"?

The American Concrete Institute (ACI) defines cold weather concreting as processes that include the installation, finishing, curing, and protection of concrete in cold weather.

Cold weather is defined as three or more consecutive days with an average daily outdoor temperature of 40 degrees Fahrenheit (4 degrees Celsius) or lower for more than half of any given 24 hours.

What are the most common cold-weather concrete mistakes?

Allowing Concrete to Freeze

The concrete should be kept warm (about 10 °C) because fresh concrete could freeze at -4 °C.

Pouring Concrete Down on the Frozen Ground

A common error is pouring concrete on cold or frozen ground. When the frozen ground warms up, it might settle, causing the top of your slab to set while the bottom remains soft, resulting in surface problems such as cracking or crusting.

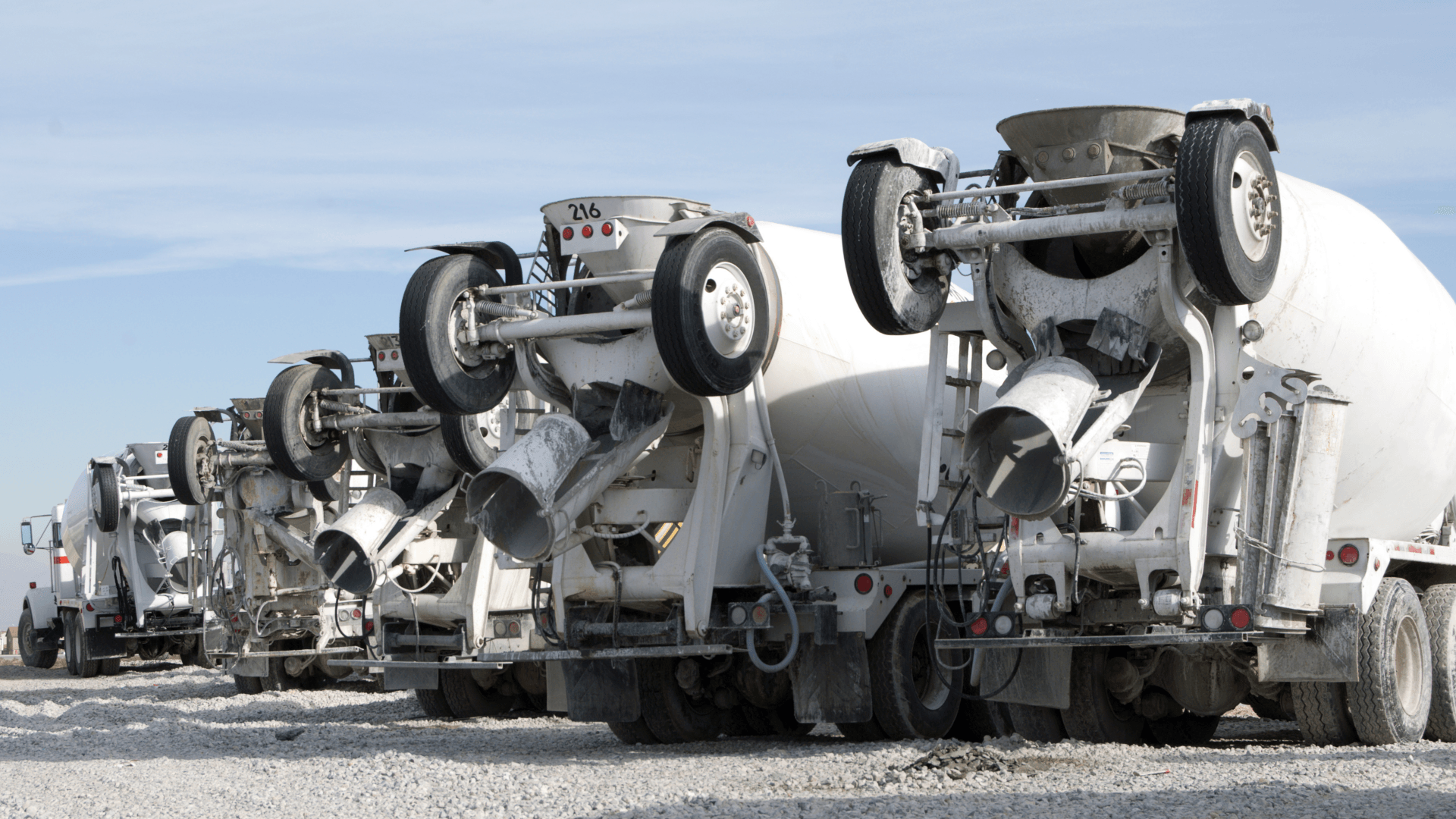

Sending Concrete Out at Improper Temperatures

The importance of good planning in cold weather cannot be understated. The concrete should arrive on time, and, from a production standpoint, the water and aggregates should be heated to maintain optimum temperatures.

Using Cold Materials

The concrete that comes into contact with the forms or tools may be affected if they are cold. It is just as essential to keep your tools and materials warm as it is to keep the concrete warm.

Not Using Heaters

As you are undoubtedly aware, the faster the concrete cures, the warmer it becomes. Allowing new concrete to cure in the cold might cause curing to halt completely. Portable heaters provide heat into the ground or a concrete pour, allowing you to operate throughout the winter.

Sealing Concrete When It's Too Cold

Sealing should be avoided if the temperature is below ten °C. It is critical to have a good suggestion from the manufacturer or producer before sealing concrete in cold weather.

Daylight Misinterpretation

The quantity of daylight decreases throughout the winter months. It is critical to manage your time effectively, as falling behind schedule can lead to even more complications. Sunlight will not only provide you with an abundance of light, but it will also provide you with warmer temperatures.

Tips for a Successful Cold-Weather Pour

Here are some crucial guidelines for concrete pours during cold weather that result in solid, long-lasting concrete.

1. Heat materials

Even in cold weather, provided the initial temperature of the concrete is sufficient, and moisture levels are appropriate, it is possible to achieve typical set times and needed strength development.

Producers may heat water to 140 °F or higher (but not above 180 °) to compensate for the effects of cold weather. When the temperature at the construction site is extremely low, it is necessary to heat materials.

2. Using accelerating admixtures

Aside from heating elements, manufacturers can employ accelerants to meet the reality of faster set times in cold conditions. Accelerating admixtures are meant to supplement, not replace, adequate cold weather protection for concrete.

Adding calcium chloride to your concrete mix can help keep its curing schedule on track.

3. Apply for cold weather protection after pouring

ACI 306R mandates contractors to deploy heating units, insulating blankets, and enclosures after precipitation to offer considerable cold weather protection.

4. Maintain proper temperatures during extended set times

According to the American Concrete Institute, exposed, no-load, normal-set concrete requires two days of protection in typical weather and three days in cold weather. The duration of protection must be increased by 50 to 100 percent.

Concrete construction may become problematic when the weather becomes cold. Colder temperatures can cause a delay in the healing process, excessive bleeding, or the freeze-and-thaw effect. Here are our top three tips for pouring concrete properly in the winter.

5. Increase the amount of concrete mixture

Use extra cement in your concrete mixture to raise the temperature of the concrete's reaction. You should add 100 pounds per cubic yard, although this number might vary depending on the temperature or how cold it will be on the day you decide to pour.

If you choose this option, make sure you have at least three days of beautiful weather and above-average overnight temperatures before you pour the concrete.

6. Use hot water

Some concrete mixtures include instructions on how to utilize them in cooler temperatures. Concrete sets in at the least three days if the temperature stays above 40°F.

If this isn't an option, consider mixing your cement with hot water rather than cold or lukewarm water to guarantee that curing and hydration are adequate and that you do not end up with a brittle concrete slab.

7. Avoid using Deicers

The combination of bad cold weather concreting and uncontrolled deicer application is particularly hazardous. Specifically, ammonium nitrate and ammonium sulfate are incompatible with freshly installed concrete surfaces.

Do You Need Professional Help With Cold Weather Concrete Jobs? Contact us anytime!

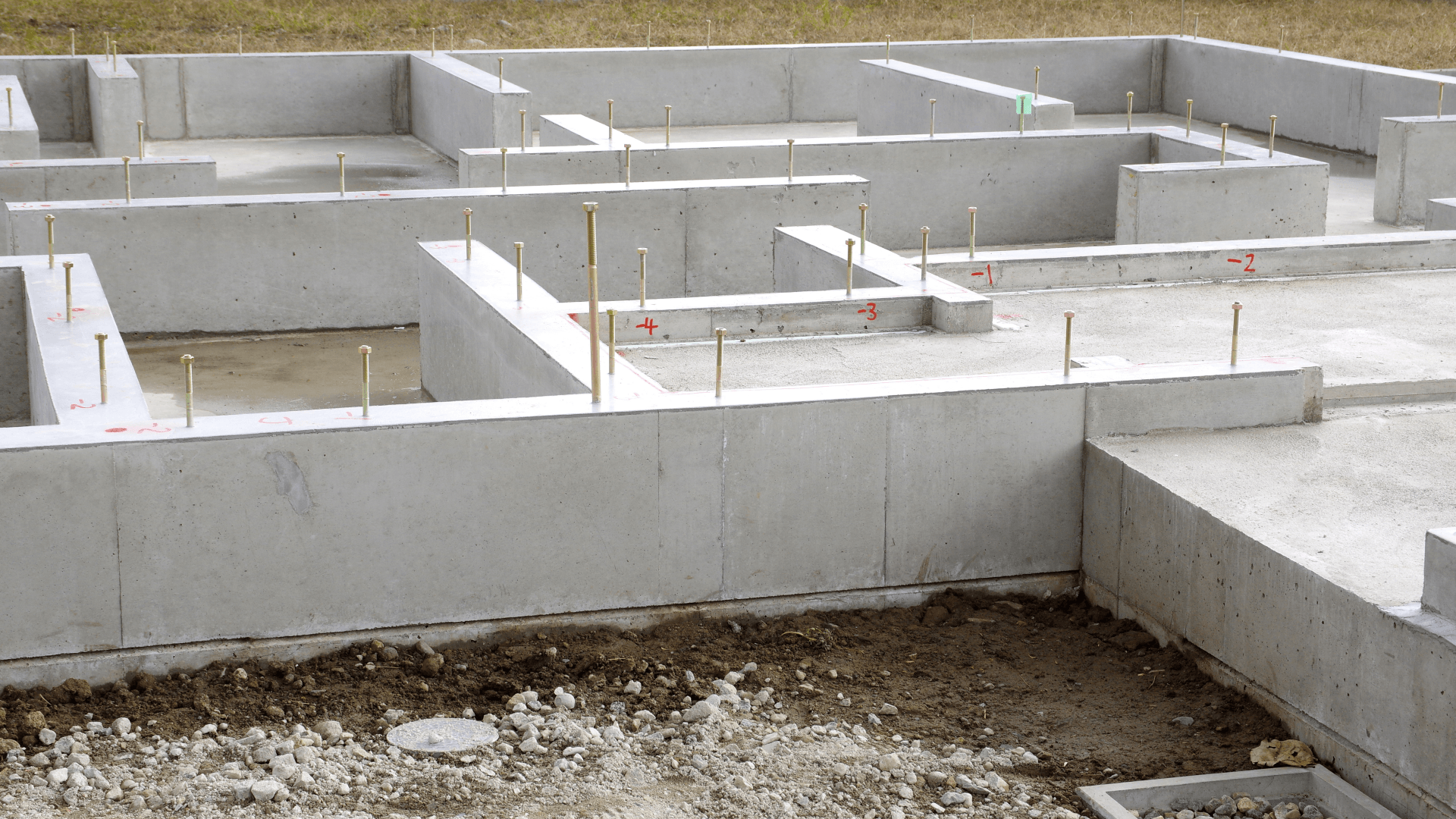

Maintaining the perfect temperature necessary for curing and setting concrete becomes challenging during cold weather.

All of the above preventive measures can assist to a certain extent. Still, expert intervention is necessary since they know how to manage temperature as much as possible so that your concrete provides the appropriate strength for your project.

Over the years, Concrete Contractors of Fargo, ND, has established itself as a leading contractor in the Fargo, North Dakota area. Our experts provide all of the services you require, such as Fargo foundation repair, stamped concrete in Fargo, concrete patio installation or repair, driveway replacement, and cold weather concreting.